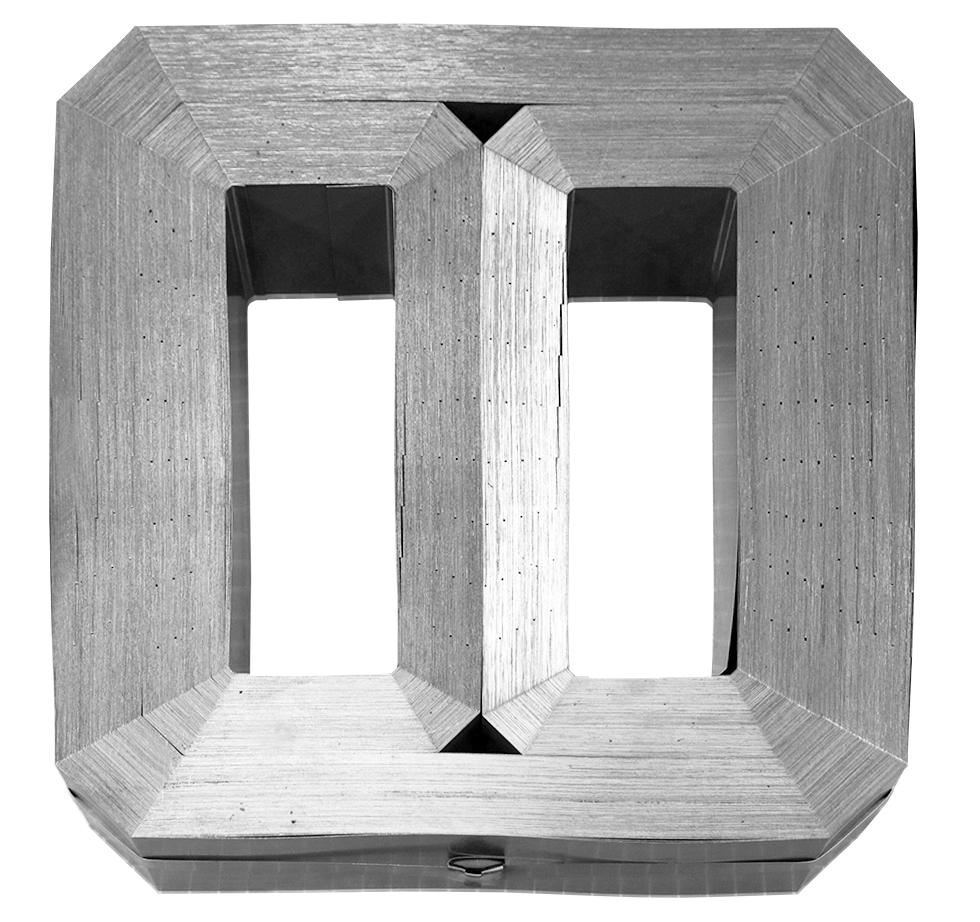

The UNICORE technology is very flexible and does not require any fixed tooling, such as various jigs or mandrels, to make the customer’s request cores, with strong reduction of production costs. Used for the power transformers, the UNICORE have lower losses (about 30%) than cut cores or EI laminations types by saving energy and dimensions core reduction. The range of the UNICORE for power transformers, extend from 1000 VA until to 500 KVA. UNICORE are largely used for power and mesure transformers using any grade of Grain Oriented Silicon Steel and can be produced in different thickness (0,23 to 0,30 mm) and strips widths (20 to 300 mm). UNICORE can be produced with 30° – 45° corners, depending on applications. DUO and DG cores may be produced, on customer request, in 1-2-3 steps with different mounting time. UNICORE can weight up to 1000 kg or more. Window sizes, build up, strips width and thickness, corners angles and type of UNICORE have to be specified. 1. Insert the first full size inner lamination into the coils. These cores are made on grain oriented silicon steel destinated to mono and trhee phases electrical transformers.

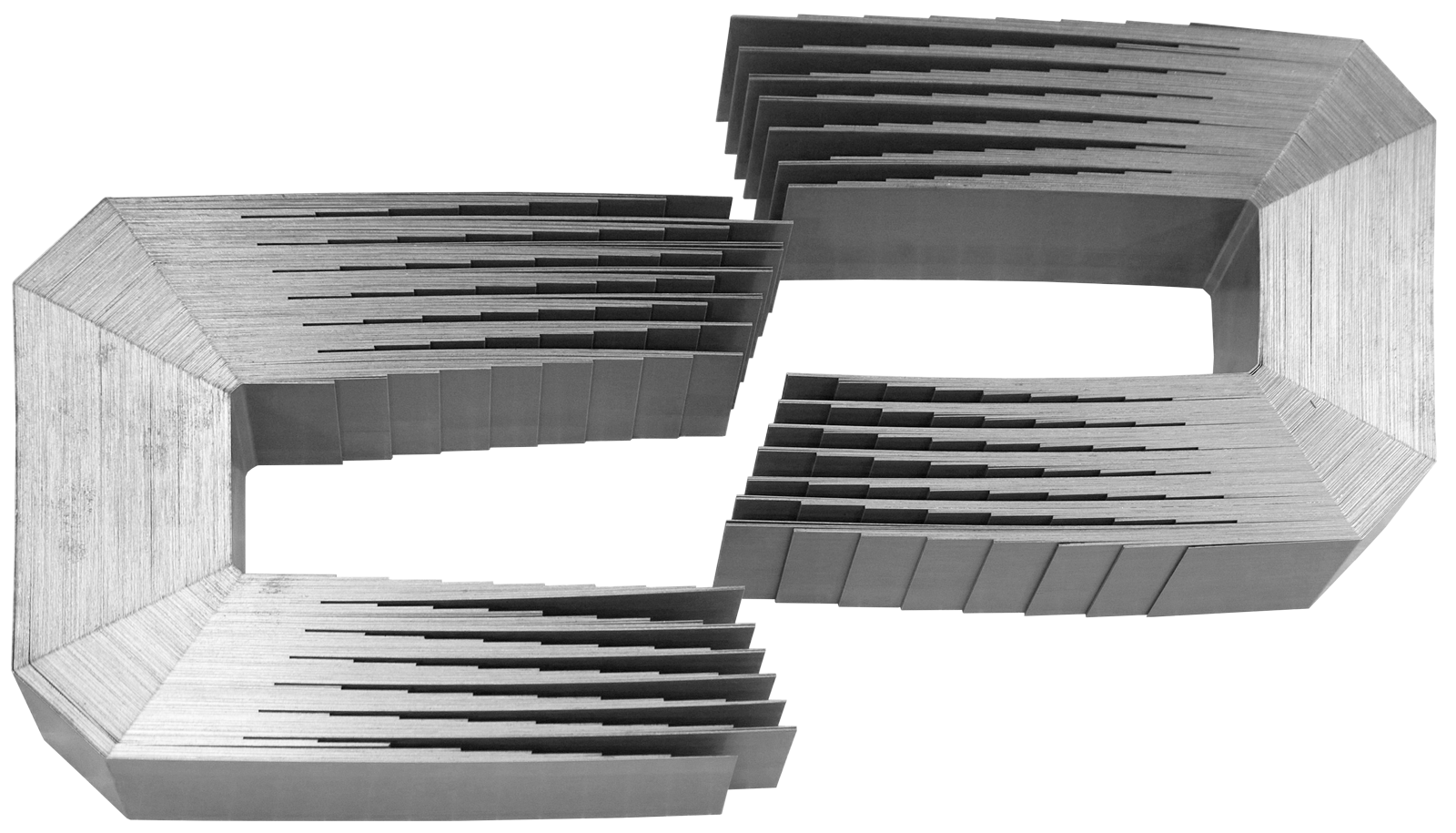

Assembly

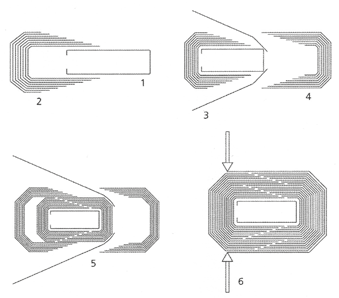

2. Insert the smallest male packet.

3. Insert the helper strips.

4. Insert the corresponding female packet and then remove the strips.

5. Now repeat the steps 2 to 4 until all packets including the last half female with the outer welding lamination have been inserted.

6. After welding the outer lamination an insulation material may be used to lightly wedge the remaining space between the core and the coil.

Contact us for a free quote or more information